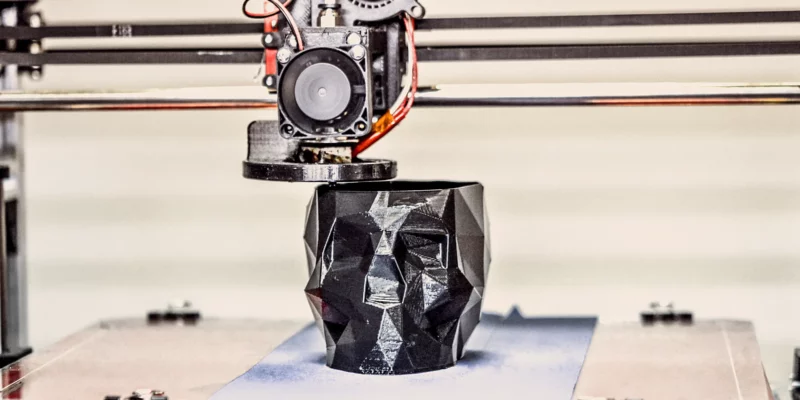

3D printing is a process of creating three-dimensional objects from a digital file. The process is additive, meaning that the object is created by adding material layer by layer until the final object is created. 3D printing is a rapidly growing technology with a wide range of potential applications.

History of 3D printing

The origins of 3D printing can be traced back to the early 1980s when a number of different technologies were developed for creating three-dimensional objects. The most important of these technologies was stereolithography (SLA), which was invented by Charles Hull in 1983. SLA uses a laser to cure a liquid resin layer by layer, creating a solid object.

In the early years, 3D printing was a very expensive technology that was used primarily by research institutions and businesses. However, the cost of 3D printers has steadily decreased in recent years, and the technology is now accessible to a wider range of users.

Types of 3D printing

There are many different types of 3D printing technologies, each with its own advantages and disadvantages. Some of the most common types of 3D printing technologies include:

- Stereolithography (SLA): SLA is a process that uses a laser to cure a liquid resin layer by layer, creating a solid object. SLA is a very precise process that is often used to create prototypes or models.

- Fused deposition modeling (FDM): FDM is a process that uses a heated nozzle to extrude melted plastic, which is then deposited layer by layer to create a solid object. FDM is a relatively inexpensive process that is well-suited for creating functional objects.

- Selective laser sintering (SLS): SLS is a process that uses a laser to fuse powdered material together layer by layer, creating a solid object. SLS is a very versatile process that can be used to create objects from a wide range of materials.

- Multi Jet Fusion (MJF): MJF is a process that uses a print head to deposit a powder material, and then a print head to fuse the material together layer by layer. MJF is a very fast process that is well-suited for creating prototypes or small production runs.

Applications of 3D printing

3D printing has a wide range of potential applications, including:

- Prototyping: 3D printing is often used to create prototypes of new products. This allows designers to test out new designs and make changes before they go into production.

- Manufacturing: 3D printing can be used to manufacture a wide range of products, including toys, tools, and medical devices.

- Education: 3D printing can be used to create educational materials, such as models and simulations.

- Arts and design: 3D printing can be used to create custom jewelry, furniture, and other objects.

- Construction: 3D printing can be used to create custom buildings and other structures.

- Healthcare: 3D printing can be used to create custom medical devices, such as prosthetics and implants.

Benefits of 3D printing

There are many benefits to using 3D printing, including:

- Customization: 3D printing allows for the creation of custom objects that are tailored to the specific needs of the user.

- Speed: 3D printing can be a very fast process, especially for prototyping.

- Versatility: 3D printing can be used to create objects from a wide range of materials.

- Cost-effectiveness: 3D printing can be a cost-effective way to produce small quantities of objects.

- Sustainability: 3D printing can help to reduce waste by reducing the need for traditional manufacturing processes.

Challenges of 3D printing

There are also some challenges associated with 3D printing, including:

- Accuracy: 3D printing can be a relatively inaccurate process, especially for complex objects.

- Material selection: The range of materials that can be used with 3D printing is still limited.

- Post-processing: 3D printed objects often require post-processing, such as sanding, painting, or heat treatment.

- Safety: There are some safety concerns associated with 3D printing, such as the potential for objects to be created that could be used for harmful purposes.

Future of 3D printing

3D printing is a rapidly evolving technology with a bright future. As the technology continues to develop, it is likely to become more accurate, efficient, and cost-effective. This will lead to increased adoption of 3D printing for a wider range of applications.

In the future, 3D printing is likely to have a major impact on many industries, including manufacturing, healthcare, and education. It has the potential to revolutionize the way we design, manufacture, and use products.